Safety, efficiency, and reliability are paramount in successful drilling rig operations. This blog post highlights the crucial significance of utilizing high-quality dies and inserts in the oil and gas industry. These seemingly small components play a critical role in ensuring worker safety, maximizing efficiency, and minimizing downtime. Investing in top-notch dies and inserts not only prevents accidents but also leads to long-term cost savings.

Safety First

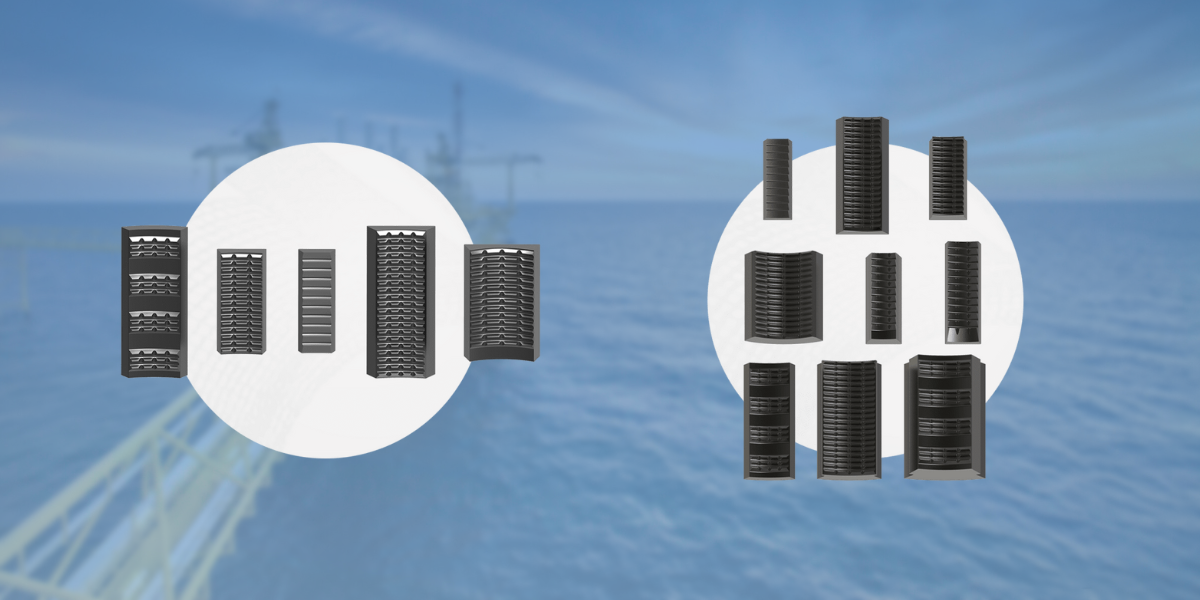

In the high-risk environment of drilling rigs, safety must always be the top priority. Dies, also known as Tong Dies, Strip Dies, or Rig Dies, are instrumental in enabling tubing tongs to securely grip Oil Country Tubular Goods (OCTG) without causing damage. Using the correct die for specific equipment is vital to prevent accidents during drilling operations.

Quality dies ensure a proper fit, reducing the risk of slippage or mishandling that could lead to hazardous situations. Similarly, inserts, also known as slip inserts or handling tool inserts, are equally significant for slip and elevator performance and reliability. These inserts are made from top-quality materials and heat-treated to enhance their durability.

For instance, specialty inserts like the Keystone Energy Tools KEY-GRIT Dies and Inserts, coated with tungsten carbide, offer exceptional resistance to wear and damage when handling challenging materials like Corrosion Resistant Alloys (CRA) tubulars. The use of high-quality inserts significantly reduces the risk of accidents and equipment failures during operations involving CRA tubulars, making them a go-to choice for experts in the industry.

Purchase Quality Dies and Inserts

To create a safer working environment and ensure optimal performance, it is of utmost importance to invest in high-quality dies and inserts. Reputable manufacturers like Keystone Energy Tools LLC offer a wide range of dies and inserts in various sizes, tolerances, and types, ensuring that rig operators can find the perfect fit for their specific requirements.

Expert Assistance

Selecting the right components for a drilling rig can be a daunting task. Fortunately, companies like Keystone Energy Tools provide expert assistance in choosing appropriate dies and inserts to complete rig work safely and efficiently. Their knowledge and experience in the industry can be invaluable in ensuring the success of a rig's operations.

Conclusion

The significance of using high-quality dies and inserts in drilling rig operations cannot be emphasized enough. Safety, efficiency, and reliability all hinge on the caliber of tools employed. While investing in top-notch dies and inserts may come with a higher initial cost, the long-term benefits are substantial, including accident prevention, reduced operating expenses, and the seamless functionality of drilling rigs. Never compromise on safety and efficiency – opt only for the finest dies and inserts for your drilling operations.

Choosing Keystone Energy Tools ensures complete confidence in the capabilities and experience of their team. Their commitment to manufacturing excellence is evident in every product they deliver, proudly made in the USA. Experience the unparalleled difference of collaborating with industry-leading experts by making Keystone Energy Tools your trusted partner for all your drilling needs.

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.